- #Art cam 2011 material setup manual

- #Art cam 2011 material setup portable

- #Art cam 2011 material setup software

there is upper and lower turret, also some have milling option.Į. depend on machine type, there is 12 slot – 16 slot. turret : component to clamp the turning tools. that's mean long part doesn't blend at the midle.ĭ.

steady rest : component to make long part have a precission cilyndrical. live centre : component to clamp work piece at tail stock, this is to get long part to be cutting was centre as well.Ĭ. this is not like table as milling machine because this part will turn at the main spindle.ī. chuck : component to clamp the workpiece.

#Art cam 2011 material setup manual

There is 3 type of machine, that is manual machine, NC machine, and CNC machine.Ī. What's turn? Turning is the machining process of hard material or soft material with lathe machine.

#Art cam 2011 material setup software

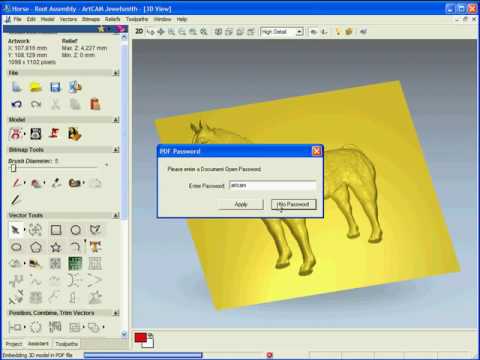

)įeaturecam is CAM software from delcam that have many function such as 2D machining, 3D machining, Turn, Mill/ Turn, Wirecut.įrom that many feature from featurecam, we now can learn turning. If you had any information, or you can add your command bellow. Then we can analyse the deviation of reegineering process.Īdding some texture from relief / another stl to solid/ surface.ĭelcam powermill-provides the solution for Tribrid manufacture effortlessly handling combinations of solid/surface and triangle data.

#Art cam 2011 material setup portable

portable scanner (with laser or probe)įor the type from common user are: roland scanner, faro arm, konica minolta scanner, etc.Īfter we get the stl data, then we input to delcam copycad. delcam support the stl data and also give dmt dataġ. The type of scan data were point cloude or stl.

0 kommentar(er)

0 kommentar(er)